Clutches

EIDE designs and manufactures locally pneumatic and electromagnetic clutches.

- Air clutches work similarly to a pneumatic cylinder, in which an air chamber pushes a rotor into a clutch disc and thus transmits torque of force. Torque transmission can go from the rotor to the clutch disc or vice versa.

- The NE model is a compact friction pneumatic clutch that transmits torque when air pressure is applied and disengages when pressure is no longer applied, thanks to springs released by the clutch discs.

- The NE/CD model is a very compact toothed pneumatic clutch that transmits torque when air pressure is applied and disengages when pressure is no longer applied.

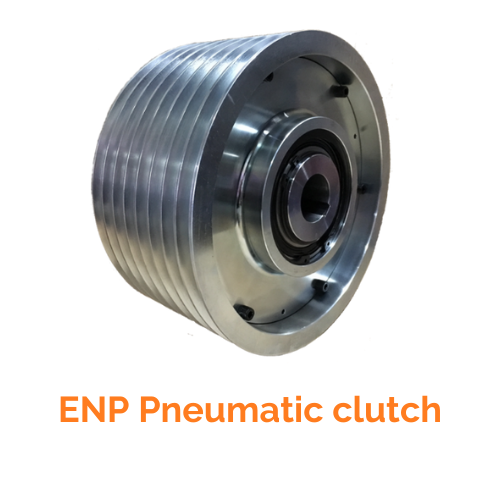

- The ENP model is a very compact friction clutch with integrated pulley. Engages with air pressure and releases without pressure.

- The EN model is a double-acting toothed pneumatic clutch. It is activated or deactivated depending which air chamber is receiving pressure.

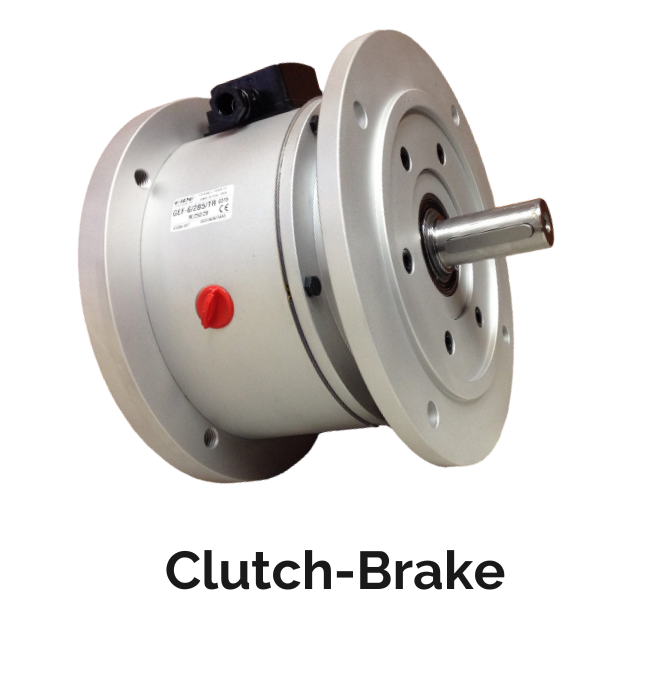

- Electromagnetic clutches work similarly to an electromagnet, in which, a steel coil and core induce a magnetic field that passes through a rotor and finally attracts the induced disc. The transmission of the torque can go from the rotor to the induced disc or vice versa.

- The SEE model is a positive clutch, that is, activated by current. It is formed by the inductor core with its corresponding coil, the rotor with the friction material incorporated and the induced assembly, composed of the induced disc itself with a spring-membrane and the induced support.

- The SER model is a positive clutch, just like the SEE model. The main difference is that it has a bearing that holds the inductor and rotor together.

- The SED model is a toothed clutch, for this reason, it must be connected at a standstill or at low speed, depending on the inertia of the system. Disengagement can be carried out at any rotational speed. The inductor is static.

- The ECD model, is a toothed clutch allows high rotation speeds thanks to the fact that it has no moving parts. The electrical connection must be made through brushes, as in electric motors.

At EIDE, we focus on delivering high quality and durable products, with a focus on customer satisfaction.

If you need more information about these devices or any other industrial component, do not hesitate to contact our technical team to make sure you are using the safest and most efficient systems in your workplace.

Fecha:

20/05/2022