Description

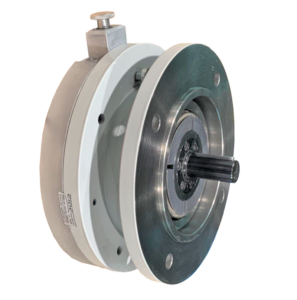

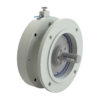

What is the DBQ centrifugal brake?

The DBQ centrifugal brake addresses the need to install a centrifugal brake and a safety brake on the same lift.

They operate by centrifugal force, without additional external power supply, which makes them suitable for security applications.

Operation without an external power supply

The centrifugal brake DBQ operates by centrifugal force, eliminating the need for an external power supply. This makes it an ideal choice for security applications.

Designed for nominal motor speeds

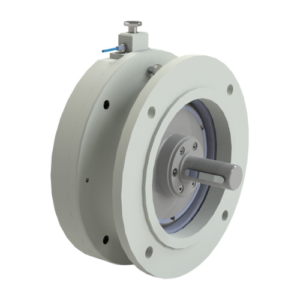

The DBQ brake is designed for easy mounting between motor and gearbox, with IEC B5 standard flanges, suitable for speeds of 1500 rpm or 1800 rpm.

The centrifugal brake operates at 10-20% above nominal speed, and the FPC safety brake between 30% and 50%. This makes it impossible to perform parachute brake tests if a centrifugal brake is also installed on the hoist.

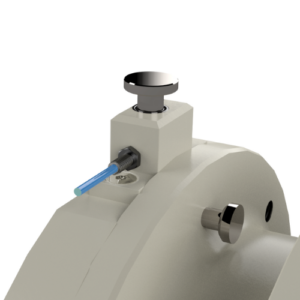

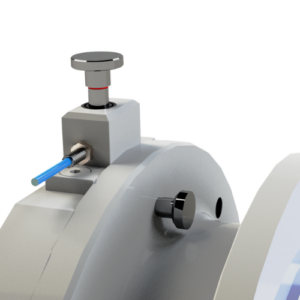

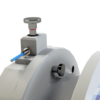

Quick and easy deactivation

Its outstanding feature is the possibility of being disabled quickly and easily through a specific mechanism.

Maximum security and versatility

Mounting a centrifugal brake DBQ together with an FPC safety brake in an elevator provides an exceptional level of safety.

Additionally, the ability to test both brakes without dismantling any components offers efficiencies unique in the industry.

Detailed operation of the centrifugal brake DBQ

The motor and brake rotate at a higher rated speed with the brake on. If, for any reason, the brake speed exceeds the nominal speed, the masses overcome the force of the springs and rub against the inner wall of the stationary drum, causing brake friction.

The motor and brake run above rated speed with the brake disabled. When a safety brake test is desired, the centrifugal brake is disabled so that the masses do not exert any braking force; thus, the brake behaves as a passive element and allows the speed to increase sufficiently for the safety brake to come into operation.

Contact our technical team

Contact us for more information on how this brake can meet your braking needs effectively and reliably