Description

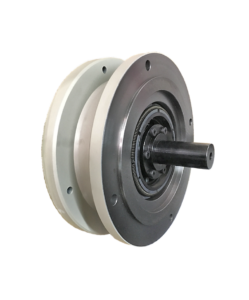

What is the EC centrifugal brake?

This brake is an essential component in the safety of cranes, industrial lifts and any machinery involving the lifting of loads.

These braking systems are designed to prevent uncontrolled falls and work on an ingenious principle based on centrifugal force.

How does the EC centrifugal brake work?

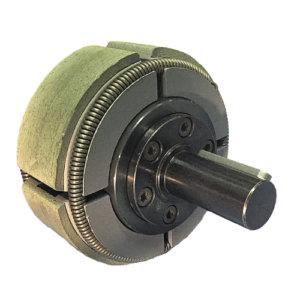

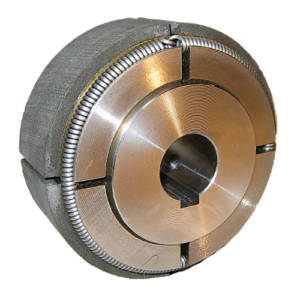

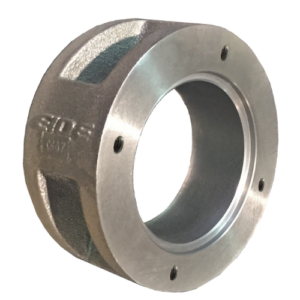

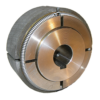

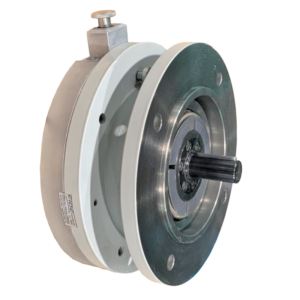

When the rotational speed increases, the masses equipped with friction material in the EC centrifugal brake overcome the resistance of the retaining springs and come into contact with the static drum. This contact creates a balance between centrifugal force and weight, keeping the speed constant throughout the stroke. The beauty of this system is that it does not require an external power supply, making it an ideal solution for safety applications.

Corrosion protection

The external part of the EC brake is coated with a layer of paint that acts as a protective barrier, preventing the formation of rust and protecting the steel from adverse environmental conditions.

Versatility of assembly

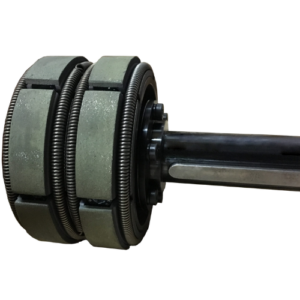

The centrifugal brake can typically be mounted between the motor and gearbox using IEC B5 standard flanges and shafts. In addition, it can be customised to suit specific applications.

Rated speeds

They are designed for applications with rated speeds of 1000, 1500 or 1800 rpm, making them suitable for a wide range of industrial applications.

Safety in case of failure

In the event of a failure of the motorisation or the main engine brake, the centrifugal brake EC is automatically activated to control the safe lowering of the load.

Common applications of the EC centrifugal brake

The EC centrifugal brake is found in a variety of critical applications, including cranes, industrial lifts and hoists.

It is also essential in passenger lifts on building construction sites and wind towers, ensuring safety on these tall structures.

The EC brake is a reliable and efficient solution that harnesses centrifugal force to maintain safety in industrial environments.

They always comply with safety standards, such as EN 1495, and are the preferred choice to ensure safe and controlled lifting operations.

| Requirement | Centrifugal Brake | Power-off Brake |

|---|---|---|

| Power Source | None (Autonomous) | Electric (24VDC / 103VDC / 195VDC) |

| Primary Function | Speed limitation during descent | Holding and emergency stopping |

| Activation | Automatic by RPM (Centrifugal force) | On/Off signal |

Contact our technical team

Contact us for more information on how this brake can meet your braking needs effectively and reliably.