Description

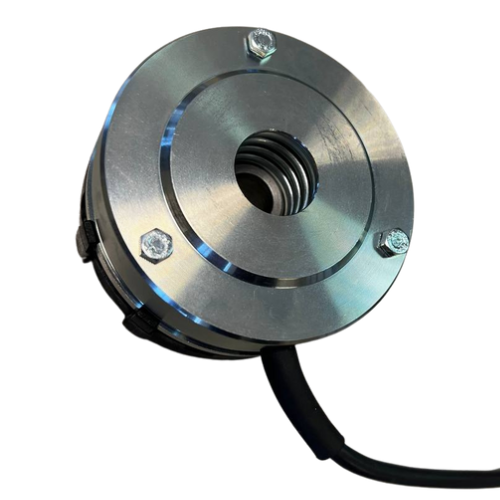

What is the FLC electromagnetic spring brake?

The electromagnetic spring brake FLC (IP54/55) from Precima Magnettechnik is a reliable and economical solution for applications requiring static torque or low-intensity work, such as emergency shutdowns.

Manufactured by the renowned German firm Precima Magnettechnik, this electromagnetic brake stands out for its efficiency and versatility.

Low price and reliable performance

One of the key advantages of the FLC brake is its affordability without compromising on quality. This electromagnetic brake offers reliable performance at an affordable cost, making it an attractive option for a wide range of applications.

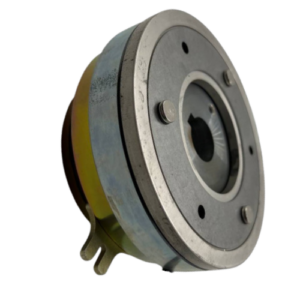

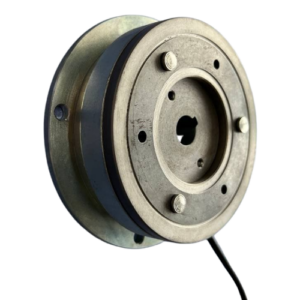

Single spring design

The single spring design makes it easy to install and maintain. This not only saves time, but also reduces the complexity of brake assembly.

Fixed air gap

One of the strong points of the FLC brake has a fixed air gap, eliminating the need for complicated adjustments. This further simplifies installation and ensures consistent performance over time.

Compact design

The FLC electromagnetic spring brake is available in three different sizes, with a torque range from 0.25 Nm to 5 Nm. This allows users to select the variant that best suits the needs of their specific application, providing flexibility in choosing the right brake.

Versatile applications

The FLC of Precima Magnettechnik is perfectly suited to a variety of applications, including industrial machinery, conveyor systems, and emergency stop situations. Its ability to provide reliable braking makes it a first-class choice in environments where safety and performance are paramount.

Easy and quick to assemble

The FLC brake assembly process is quick and easy, reducing downtime and improving installation efficiency. This is especially valuable in production and manufacturing environments where time is a critical resource.

Contact our technical team

Contact us at to find out more about how this brake can effectively and reliably meet your needs.

For more information about the products we have in EIDE, please contact us at contact with us.