Description

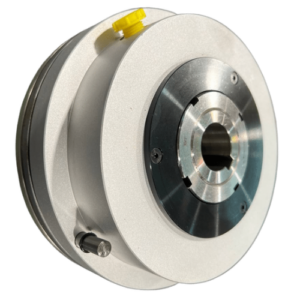

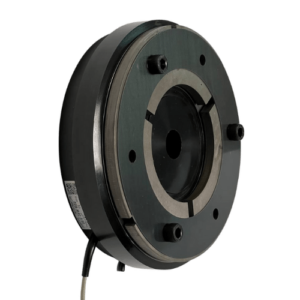

What is the NE pneumatic clutch?

The NE pneumatic clutch is an innovative compact unit that combines clutch and release functions using air pressure.

This device is essential for transmitting the torque between the conductive and driven parts in various industrial applications.

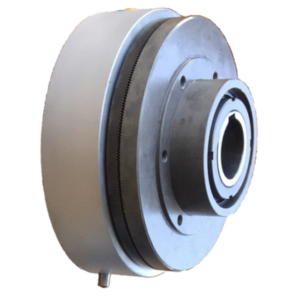

Efficient power transmission

When air pressure is applied to the actuation chamber of the NE pneumatic clutch, it engages and transmits the torque required to operate the machinery.

This mechanism is based on the adhesion effect that occurs between the friction material and the clutch disc when air pressure is applied, allowing efficient power transmission.

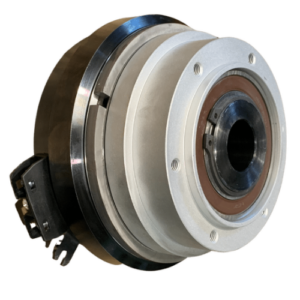

Torque and acceleration control

An outstanding feature of this clutch is the ability to control the acceleration of the machine and limit the transmitted torque. This is achieved by properly regulating the air pressure in the drive chamber.

This versatility in control is essential to ensure the safety and optimum performance of other machine components.

Efficiency in air consumption

Despite its compressed air-based operation, the NE pneumatic clutch is highly efficient in air consumption. The air chamber is static, which means that air consumption is minimal. This is beneficial from both an economic and environmental point of view.

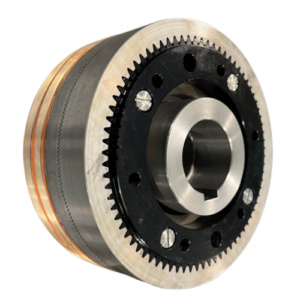

Crucial clutch selection

Choosing the right clutch is critical to the optimum performance of any application.

If the clutch cannot transmit all the required torque, slippage will occur between the contact surfaces, resulting in heat and premature wear.

It is therefore essential to select the NE pneumatic clutch that suits the specific needs of the application.

Maintenance and cleaning

To ensure efficient operation and prolong the life of the NE air clutch, it is important to keep the friction surfaces free of grease or oil. Any contamination on these surfaces can adversely affect the performance and durability of the clutch.

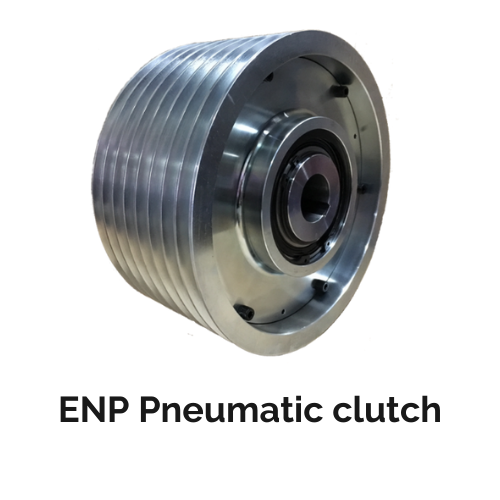

No rotary air intake required

Unlike some pneumatic clutch systems, the NE pneumatic clutch does not require a rotating air intake. The air chamber is static, which simplifies installation and reduces system complexity in industrial applications.

Friction coefficient range

The coefficient of friction is a critical factor in the performance of pneumatic clutches. In general, clutches have a coefficient of friction ranging from 0.3 to 0.45, which allows them to be adapted to various applications and power transmission needs.

Contact our technical team

Contact us at for more information on how this clutch can effectively and reliably meet your needs.

For more information about the products we have in EIDE, please contact us at contact with us.