Description

What is an Air Rotary Joint?

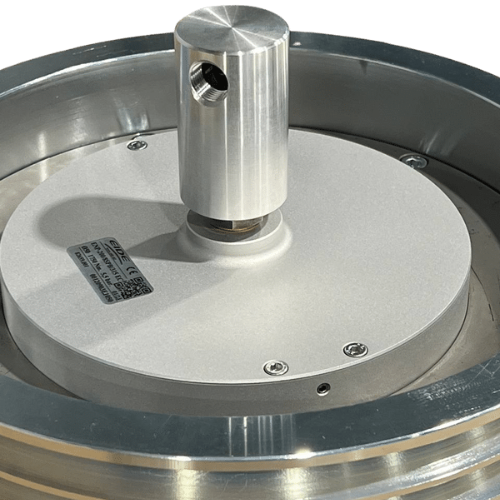

The air rotary joint is designed to allow airflow between a stationary source and rotating components, such as shafts or cylinders, in a machine or system.

These seals are crucial in applications where compressed air or vacuum needs to be supplied to rotating machinery parts.

Optimising power transmission with rotary joints: A focus on tight sealing and efficiency

The air rotary joint plays a crucial role in transmitting pressurised fluids, such as hydraulic oil, air or vacuum, from a fixed supply line to rotating components of a machine or cylinder.

These ingenious parts act as vital links, enabling the efficient transfer of power through rotating shafts, such as a machine shaft, while maintaining a tight seal.

Watertight sealing for optimum performance

One of the fundamental aspects of a rotary air seal is its ability to provide a tight seal, ensuring that there is no leakage between the pressurised supply line and the rotating machine or cylinder.

This sealing is essential to ensure leak-free performance and maintain system integrity. Advances in sealing technology have led to increasingly efficient designs that minimise the risk of failure and maximise durability.

Versatility in fluid transmission

Rotary joints are versatile and can handle a variety of fluids, including hydraulic oil, air or vacuum.

This versatility makes them suitable for a wide range of industrial applications where smooth power transmission is required.

From hydraulic systems controlling heavy machinery to applications involving compressed air or vacuum, rotary joints play an integral role in a variety of industrial environments.

Efficiency and reliability in secure environments

Designed for use in non-explosive environments and with non-combustible fluids, rotary joints offer reliable and safe performance.

The selection of robust materials and attention to manufacturing standards contribute to the durability and strength of these seals in demanding industrial environments.

Contact our technical team

Contact us for more information on how these accessories can effectively and reliably meet your needs.

For more information about the products we have in EIDE, please contact us at contact with us.

ENP Pneumatic Clutch

ENP Pneumatic Clutch