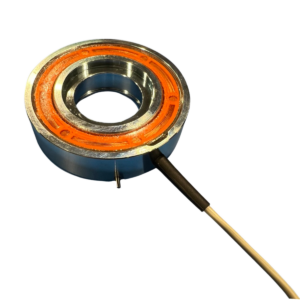

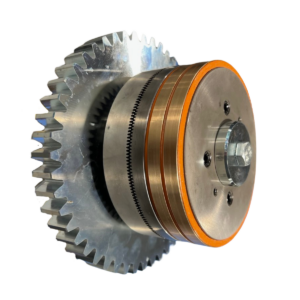

EIDE Adopts Additive Manufacturing for Sustainable Plastic Parts Production

At EIDE, we continuously strive to improve our production processes, aligning with sustainability goals while enhancing efficiency. In a revolutionary shift, we have transitioned from traditional machining to additive manufacturing to produce plastic components for our industrial clutches and brakes. This change not only represents a technological advancement but also highlights our strong commitment to reducing environmental impact. Thanks to this innovation, we’ve reduced plastic consumption by up to 95%, setting a new benchmark in sustainable manufacturing practices.

Why Choose Additive Manufacturing?

Additive manufacturing—also known as 3D printing—offers a transformative approach to component production. Unlike traditional machining, which removes material from a larger block, additive manufacturing builds parts layer by layer, using only the exact amount of material required. This process eliminates excessive waste and allows for more complex and innovative designs.

For EIDE, this transition brings significant benefits:

- Material Efficiency: Drastically reduced plastic usage, minimizing waste.

- Cost Optimization: Lower resource consumption and streamlined production processes lead to more cost-effective manufacturing.

- Design Flexibility: Complex geometries and custom designs can now be produced more efficiently.

For more details on additive manufacturing, visit this Wikipedia article.

Key Benefits for EIDE Products

Integrating additive manufacturing has improved both the quality and sustainability of our clutches and brakes, offering:

- Precision and Performance: Consistent quality and accuracy, resulting in enhanced plastic components for our products.

- Durability and Lightness: Optimized material use produces lightweight yet highly durable parts that meet the highest industrial standards.

- Environmental Sustainability: With up to 95% less plastic used, we significantly lower our carbon footprint, contributing to a greener future.

Our Commitment to Sustainability

Sustainability is a core pillar of our operations. At EIDE, we recognize the importance of reducing environmental impact while continuing to deliver exceptional-quality products. Additive manufacturing plays a crucial role in this mission by:

- Reducing plastic consumption in production.

- Lowering energy usage compared to traditional machining.

- Creating longer-lasting components, decreasing the need for frequent replacements.

A Step Toward the Future

Our decision to integrate additive manufacturing into our production process reflects not only our commitment to technological innovation but also our vision for a more sustainable future. By embracing cutting-edge techniques, we are paving the way for manufacturing practices that benefit both our customers and the environment.

Partner with EIDE for Innovative Solutions

With over 65 years of experience in designing and manufacturing industrial clutches and brakes, EIDE continues to lead in quality, reliability, and innovation. Whether you need components for clutches, brakes, or custom industrial solutions, our team is ready to deliver tailor-made products. Additive manufacturing is just one of the many ways we’re enhancing the efficiency and sustainability of our operations.

Contact Us

Discover how EIDE is integrating additive manufacturing into our production processes. If you’re looking for sustainable and innovative industrial solutions, we’re here to help!