How Electromagnetic Clutches Work

How an Electromagnetic Clutch Works: The Key to Efficient Power Transmission

In the vast world of engineering and industrial machinery, electromagnetic clutches hold a special place. These devices are the perfect solution for applications that demand quick, precise, and efficient power transmission. But how do they actually work? In this article, we’ll explain it in an engaging and straightforward way so you can fully grasp their importance and impact on modern industries.

What is an Electromagnetic Clutch?

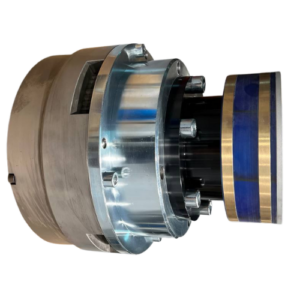

Put simply, an electromagnetic clutch is a device that uses a magnetic field to transmit power between two rotating shafts. This type of clutch is widely used in applications requiring precise control, combining advanced engineering with practical functionality.

Key Components of an Electromagnetic Clutch

While the concept may sound complex, the design relies on several components working together seamlessly:

- Electromagnetic Coil: The driving force of the system. When an electrical current is applied, it generates a magnetic field that activates the clutch. Cuando se aplica corriente eléctrica, genera un campo magnético que activa el embrague.

- Rotors: Responsible for transferring power from the clutch to the output shaft.

- Friction Disc: This part acts as the contact surface between the clutch and the shaft transmitting the power.

Each of these elements plays a critical role, but the true star of the system is the electromagnetic coil.

The Power of the Coil: How Does an Electromagnetic Clutch Work?

- Magnetic Field Generation: When an electrical current flows through the coil, it turns into an electromagnet, producing a powerful magnetic field that attracts the friction disc.

- Engagement: The friction disc, made from high-friction materials, is pulled toward the coil, creating a strong connection that transmits torque from the motor to the driven shaft.

- Disengagement: When the electrical current is interrupted, the magnetic field disappears, and the friction disc separates, halting the power transmission.

This engagement and disengagement process happens in milliseconds, ensuring fast and precise responses for any application.

Advantages of Electromagnetic Clutches

Why are these devices so popular? Their benefits speak for themselves:

- Precise Control: Adjust the engagement force simply by regulating the electrical current.

- Fast Response: Instant activation makes them ideal for highly synchronized industrial processes.

- Exceptional Durability: By minimizing direct contact between moving parts, wear and tear are reduced, extending the clutch’s lifespan.

- Quiet Operation: Designed to run smoothly and silently, they are perfect for noise-sensitive environments.

Common Applications of Electromagnetic Clutches

You’ll find these devices in more places than you might think:

- Automotive: They control the operation of the vehicle’s A/C.

- Industrial machinery: Used in conveyor belts, packaging machines or production equipment.

- Home Appliances: Found in washing machines, air conditioners, and more.

The Perfect Solution for Efficient Power Transmission

Electromagnetic clutches are indispensable in modern machinery, offering reliable, precise, and efficient power transmission. Their ability to adapt to diverse industrial applications makes them a critical component in engineering.

If you’re looking for a trusted supplier offering high-quality, customized solutions, EIDE is here to help. With years of experience in manufacturing electromagnetic clutches, we deliver products designed to meet the highest performance standards

Ready to take your machinery to the next level? Contact us today and discover how our electromagnetic clutches can make a difference in your projects!