Electromagnetic Brakes: Choosing the Right Solution

Electromagnetic brakes are essential components in various industrial and commercial applications, offering precise control, safety, and reliability. With advancements in technology, different types of electromagnetic brakes have emerged to meet specific operational needs. In this guide, we will explore three main types of electromagnetic brakes: armature (disc) brakes, spring-applied brakes, and powder brakes. We’ll discuss their benefits, differences, and the ideal scenarios for their use.

What Are Electromagnetic Brakes?

Electromagnetic brakes use electromagnetic force to engage or release braking systems. Unlike traditional mechanical brakes, they offer quicker response times, lower maintenance requirements, and improved control. These features make them ideal for automation, robotics, conveyors, and many other applications.

Types of Electromagnetic Brakes

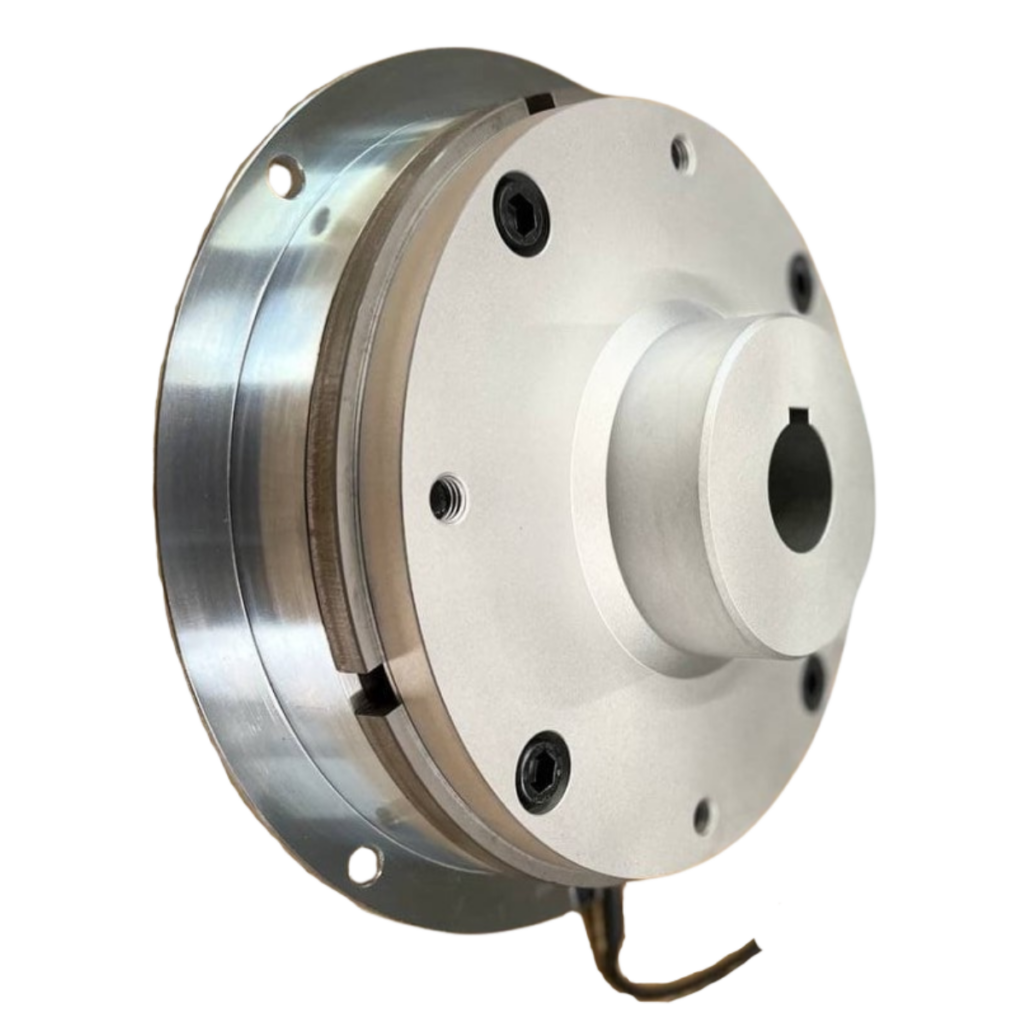

1. Armature Brakes: FAE & FAET & OMB

Armature, or disc brakes, are electromagnetic brakes that engage when electrical current is applied. They offer:

- High Precision: Ideal for applications requiring quick and precise stopping.

- Reduced Wear: Since they only engage under current, mechanical wear is minimised.

- Compact Design: Suitable for limited spaces.

EIDE offers two advanced models in this category:

PRECIMA offers one advanced model in this category:

To better serve the evolving industrial market, EIDE has integrated the OMB Precima series as our primary standard for electromagnetic brakes.

- Need it fast? We provide OMB brakes directly from stock for immediate shipping.

- Need a custom size? For applications that are outside the OMB standard range or require bespoke engineering, our EIDE-manufactured FAE series remains the flexible solution for specialised projects.

Whether it’s the precision of Precima or the custom flexibility of EIDE, we ensure your 24VDC system has the perfect braking torque.

2. Spring-Applied Brakes: FDB, FDW, FDX by PRECIMA

The spring-applied brakes (also known as failsafe brakes) engage when power is lost, making them crucial for safety applications. These brakes are perfect for emergency stops and holding positions under load.

- Failsafe Operation: Automatically engages during power failure.

- Safety Assurance: Ideal for vertical applications and critical systems.

- Durability: Withstands high-torque requirements.

PRECIMA’s spring-applied brakes include:

These models provide robust performance in scenarios where safety and reliability are paramount.

3. Powder Brakes: FMP

Powder brakes operate proportionally to the current applied, offering variable torque control. These brakes are perfect for applications requiring smooth and controlled deceleration, such as in tension control systems. Benefits include:

- Proportional Control: Allows precise modulation of braking force.

- Smooth Operation: Minimises jerks and mechanical stress.

- Versatility: Suitable for winding, unwinding, and tension control.

The EIDE FMP Electromagnetic Powder Brake is engineered to deliver consistent performance in complex industrial processes.

Comparison: Which Electromagnetic Brake Should You Choose?

| Feature | Armature | Spring-Applied | Powder |

| Engagement | When the current is applied | When power is lost | Proportional to current |

| Ideal use | Precise, quick stops | Safety and holding | Smooth deceleration or controlled |

| Application | Automation, robotics | Emergency systems | Tension control |

| EIDE models | FAE, FAET | FDB, FDW, FDX | FMP |

Electromagnetic brakes offer tailored solutions for various industrial needs. Whether you require precision stopping, safety assurance, or smooth braking, EIDE provides a comprehensive range of options, including armature, spring-applied, and powder brakes. Explore our full catalogue and find the perfect braking solution for your application.

Explore our electromagnetic brakes and safety solutions for elevators and industrial machinery.