Description

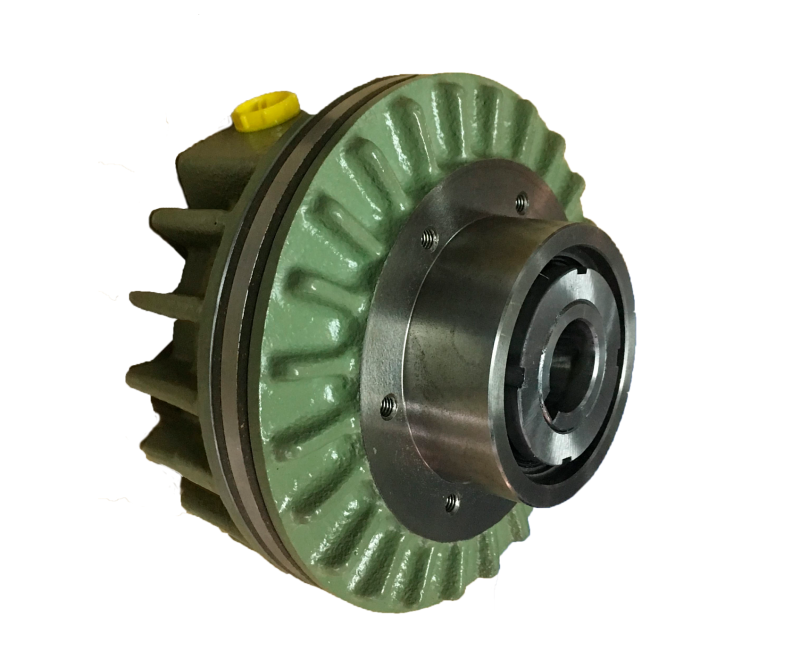

What is the NEF pneumatic clutch-brake?

The NEF pneumatic clutch-brake represents a compact and versatile solution that combines the functions of a pneumatic clutch and an antagonistic brake by means of spring action.

This device, radially supplied with compressed air at a nominal pressure of 5.5 bar, offers a wide range of industrial applications.

NEF design and features

The integration of the driving part by means of bearings and a cylindrical area with axial threaded holes allows easy adaptation, whether for the incorporation of sprockets, pulleys or flexible couplings between two shafts in line.

This versatility in design facilitates its implementation in various mechanical systems.

Precise machine control

Proper air pressure regulation not only provides effective control over the acceleration time of the machinery, but also limits the torque transmitted, ensuring the safety of the rest of the mechanism.

This air pressure control becomes a key factor in optimising performance and operational safety.

Effective integration: Solenoid valve and mounting

The recommendation to mount the solenoid valve directly on the clutch-brake body is a highlight for quick response.

This arrangement allows the elimination of the quick exhaust valve, simplifying the system and improving operational efficiency.

Practical applications

Typical NEF pneumatic clutch-brake assembly is by means of pulleys, chain discs or sprockets leading to a driven shaft, applying the brake to the latter.

This mounting versatility extends its possible applications in a wide range of mechanical configurations.

Contact our technical team

Contact us at for more information on how this clutch-brake can effectively and reliably meet your needs.

For more information about the products we have in EIDE, please contact us at contact with us.