Description

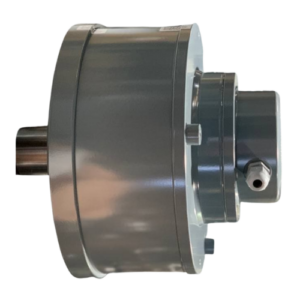

What is the Safety Brake FPC?

The Safety Brake FPC is a crucial device used in lifting and transport applications to ensure safety if the lowering speed of the load or platform exceeds a preset value.

How does the FPC work?

When the lowering speed exceeds 30% to 50% above the nominal speed, the FPC activates. Centrifugal sensors lock the brake shaft, stopping the transmission in a cushioned manner. This ensures a precise stop without sudden impacts.

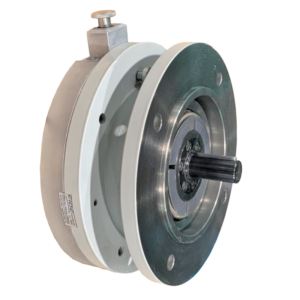

Key benefits

- Guaranteed safety: Prevents accidental falls.

- Full versatility: Ideal for construction hoists, work platforms, and wind towers.

- Smart savings: Minimises damage and reduces wear on equipment.

- Regulation-compliant: Designed to meet industrial safety standards.

Why choose the FPC?

This brake not only protects but also optimizes your investment. Its design ensures smooth stopping, increasing equipment durability and preventing costly downtime.

Use of the FPC in lifting applications complies with safety standards and industry regulations, ensuring workplace safety.

Versatile applications

The FPC is used in a wide range of applications, from construction hoists to work platforms and wind towers, demonstrating its utility across multiple sectors.

Automatic reset

After activation, the Safety Brake FPC can be automatically reset by raising the platform a few centimetres against the locking direction. Work can resume immediately without manual intervention.

Contact our technical team

Contact us to learn more about how this brake can meet your braking needs effectively and reliably.