Description

What is the FAET electromagnetic brake?

The FAET electromagnetic brake is an innovative solution designed for applications requiring precise control of the unwind tension, such as in the processing of paper, tissue or cable reels.

This positive electromagnetic brake is current driven and offers versatile control over the resistance to shaft rotation. In this article, we will explore in detail how the FAET brake and its benefits in industrial applications.

Operation of FAET electromagnetic brake

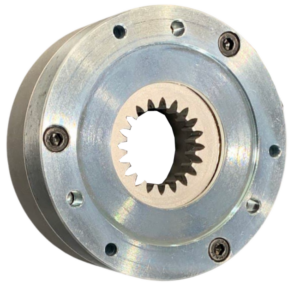

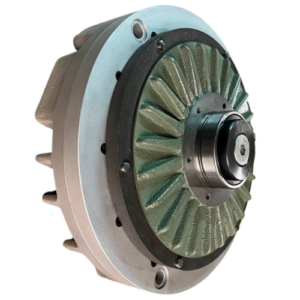

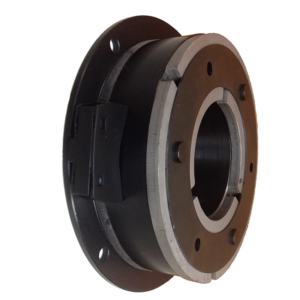

The FAET brake consists of two main components: the armature with friction material and the rotor, which includes the armature, the radiator and the hub.

Its operation is based on the application of a variable voltage of 0 to 24 V direct current. When this voltage is applied, the brake coil creates a magnetic field proportional to the voltage, thus allowing the braking torque to be precisely regulated.

This tension control is essential in unwinding applications, where maintaining a constant tension is crucial for quality processing.

Cuando se suministra una tensión continua a la bobina, se genera un campo magnético que atrae el inducido. Esto, a su vez, ejerce resistencia a la rotación del eje, lo que frena el movimiento.

In other words, the FAET electromagnetic brake acts as an active voltage controller, adjusting its braking force according to the needs of the application.

Unlocking and technical characteristics

When the brake is de-energised, it automatically disengages, allowing the axle to rotate freely.

This feature is essential in applications that require frequent changes in unwind tension.

The FAET brake is designed to operate efficiently in industrial environments where heat generation is common due to continuous use.

To address this challenge, the brake is equipped with a high-performance aluminium radiator that contributes significantly to heat dissipation. This ensures that the brake maintains consistent performance even under demanding working conditions.

Precise control

The brake allows precise control of the unwinding tension, ensuring high quality production.

Versatility

It is suitable for a wide range of applications, from paper reels to cables and textiles.

Energy efficiency

Thanks to its current-based operation, the brake consumes energy only when it is needed.

Thermal resistance

The aluminium radiator contributes to efficient heat dissipation, maintaining consistent performance in industrial environments.

Contact our technical team

Contact us to find out more about how this brake can effectively and reliably meet your needs.

For more information about the products we have in EIDE, please contact us at contact with us.