Wine Capsule

Optimizing the Capsule Manufacturing Process for Wine Bottles

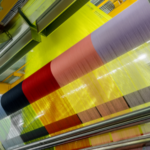

The manufacturing of capsules for wine bottles is a crucial part of the bottling process, as it not only ensures proper sealing but also plays an essential role in protecting the product. To ensure quality and efficiency in capsule production, it is vital to use advanced solutions for tension control, clutches, brakes, and torque limiters. In this article, we will explore how these technologies improve the capsule production process and ensure a perfect final product.

Tension Control in Capsule Manufacturing for Wine Bottles

Tension control is vital in the manufacturing of wine bottle capsules, especially in systems handling materials like plastics used in sealing. Tension control brakes maintain constant and precise tension in the material, preventing it from breaking or slipping during the manufacturing process. Ensuring the tension remains at optimal levels, improves consistency in cutting the capsules, reducing defects, and increasing the quality of the final product.

Clutches for Tension Control: Customized Solutions for the Wine Industry

Clutches for tension control are fundamental in capsule production, as they allow for the regulation of tension in the materials used in the sealing process. These clutches prevent slippage or breakage during production, ensuring that the capsules are made uniformly and accurately. By incorporating clutches for tension control, machines can automatically adjust tension according to the production needs, improving efficiency and reducing the risk of failure.

Clutch-Brake Systems for Capsule Application in Wine Bottles

Another key component in capsule production is the clutch-brake system, which is used in machines that apply capsules to wine bottles. This system combines a clutch and a brake to precisely control the torque during the application, preventing over-tightening that could damage both the capsule and the bottle. The combination of clutch and brake also helps reduce vibrations and torque spikes, contributing to a more uniform application and better sealing.

Torque Limiters: Protection for Production Machines

The machinery used in capsule production must be protected from potential overloads that could compromise its functionality. Torque limiters play an essential role by providing effective protection against excessive torque. These devices adjust the maximum torque according to the production process specifications, ensuring that the machines do not suffer damage and maintaining operational safety at all times. Implementing torque limiters reduces downtime and improves equipment reliability.

Benefits of Integrating Tension Control, Clutches, Brakes, and Torque Limiters in Capsule Production

Integrating advanced solutions like tension control brakes, tension control clutches, and torque limiters offers significant benefits in the capsule manufacturing process for wine bottles. These benefits include:

- Increased Precision and Consistency: Precise control of tension and torque guarantees uniform capsule application and defect-free manufacturing.

- Reduced Waste: Material waste is reduced by minimizing the risk of production failures, improving efficiency and lowering costs.

- Optimized Production Time: These systems allow for a steady production pace, preventing unnecessary stoppages and improving operational efficiency.

- Machine Safety and Durability: Torque limiters protect the machines, ensuring longevity and preventing costly interruptions.

For more details about EIDE’s solutions for wine bottle capsules, contact us here.