Machine tools

Advanced Power Transmission Solutions for Machine Tools: Precision and Safety

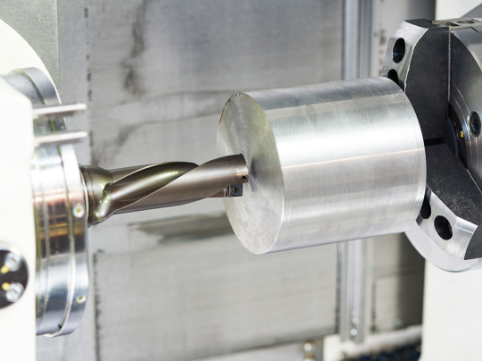

A machine tool is a stationary power tool engineered to shape, cut, drill, or machine rigid materials such as metal, wood, and advanced plastics. These systems are the backbone of modern industry, ranging from manually operated equipment to highly sophisticated Computer Numerical Control (CNC) automated systems.

Common Types of Machine Tools and Industrial Applications

The versatility of machine tools allows them to serve critical roles across multiple sectors, including aeronautics, electronics, construction, and high-volume manufacturing. Common examples include:

- Lathes: For rotational machining and turning operations.

- Milling Machines: For complex surface shaping and gear cutting.

- Grinders and Saws: For precision finishing and material sizing.

- Presses: For forming and stamping metal components.

These tools are indispensable for mass production and the fabrication of high-tolerance parts and components where accuracy is paramount.

The Evolution of Automation and Efficiency

Modern machine tools integrate advanced software and high-tech hardware to enable the automated production of high-quality components. This digital transformation has led to:

- Increased Operational Efficiency: Faster cycle times and reduced downtime.

- Cost Reduction: Lowering production overhead through precision and waste reduction.

- Enhanced Workplace Safety: Automated systems reduce the need for manual handling, significantly lowering the risk of industrial injuries.

EIDE: Engineering Excellence in Machine Tool Components

At EIDE, we specialise in the design and manufacture of high-precision power transmission components. Reliability in these components is essential to maintain the precision and safety of the machinery. Our specialised solutions include:

- Clutches and Brakes for Lathes: Ensuring smooth transitions and precise stopping during turning operations.

- Safety Brakes for Machining Centres (CNC): Providing critical fail-safe protection to prevent tool damage and operator injury in the event of power loss.

- Clutches and Brakes for Rolling Mills: Engineered to handle high torque and demanding industrial cycles.

- Couplings and Brakes for Roll Forming Machines: Facilitating accurate synchronisation and high-performance material shaping.

By integrating EIDE’s cutting-edge technology, manufacturers can transform standard machining into a controlled, high-performance industrial process. Contact our technical department to find the ideal braking or clutching solution for your specific machine tool application.

Here are the products that EIDE manufactures for machine tools.

For more information about the products that we have at EIDE, do not hesitate to contact us.